-

1 XLR 암컷(F) to USB-C 변환 케이블 (동적 마이크용 PC-노트북 녹음 케이블) 1M [ZBL034-005]

4,650 원 -

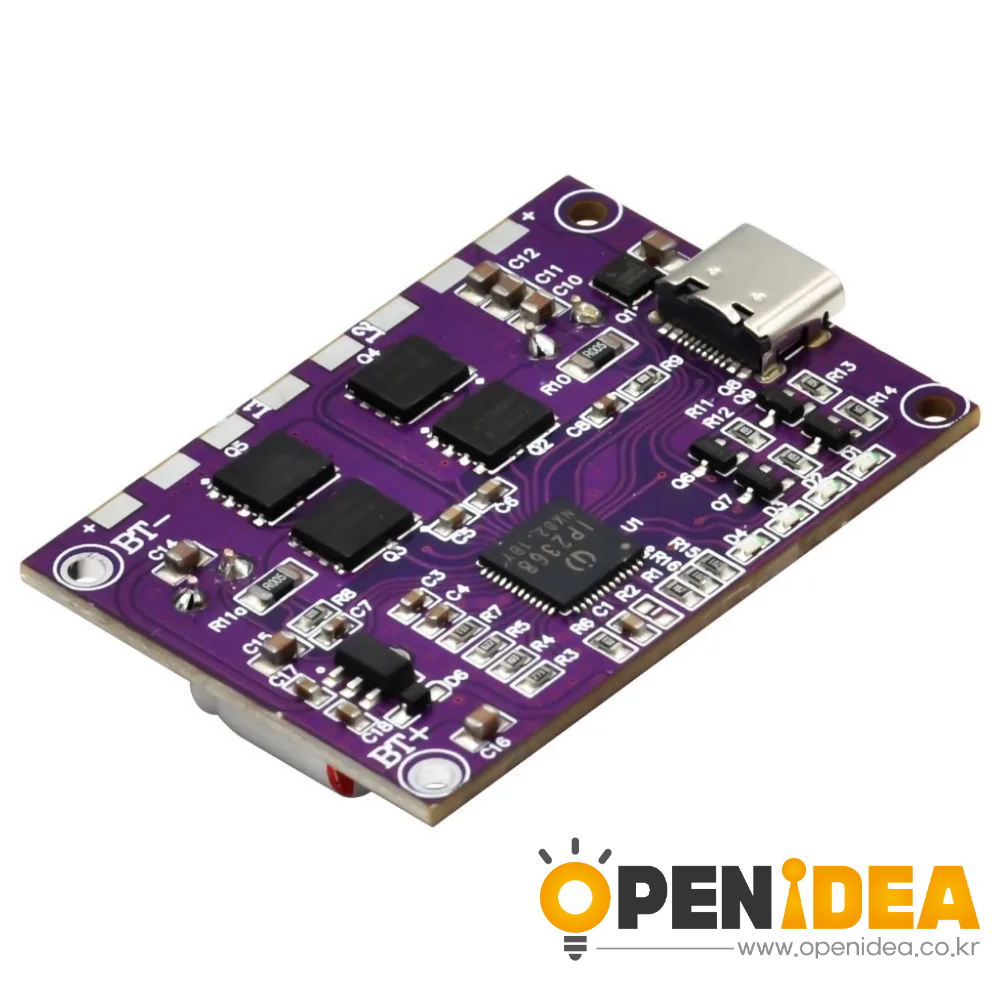

2 ip2368 양방향 고출력 고속 충전 모듈 파워뱅크 회로 기판 세트 PD100W 승강압 고속 충전 [ZTA180-325]

11,070 원 -

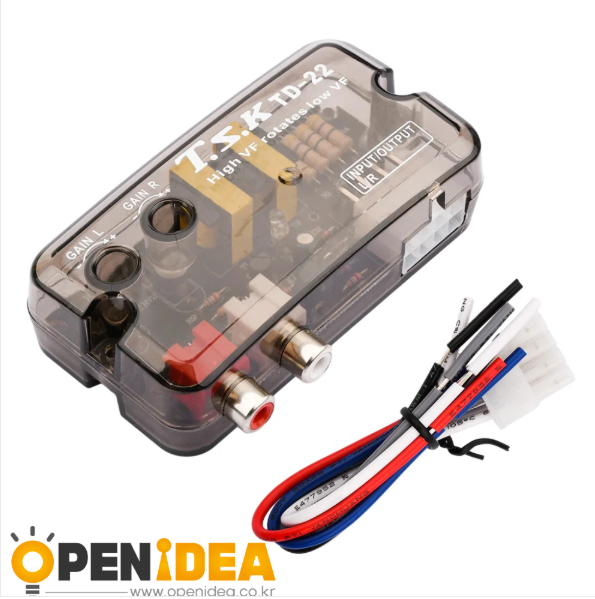

3 자동차 오디오 Hi-Low 컨버터 (서브우퍼 오디오 변환기) [ZTP50-092]

2,790 원 -

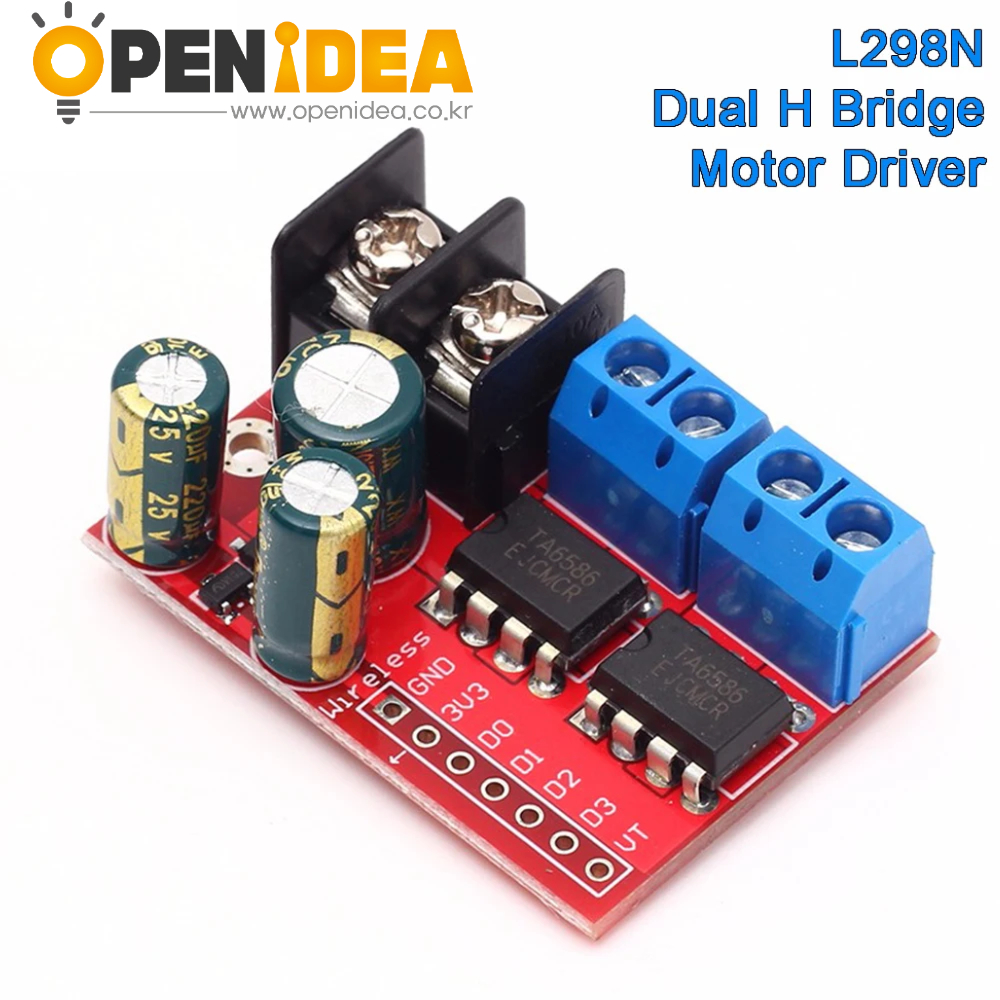

4 5A 듀얼 채널 DC 모터 드라이버 모듈 리모컨 가능 정역회전 PWM 속도 제어 듀얼 H-브리지 L298N 초월형 5A [ZTH83-011]

3,600 원 -

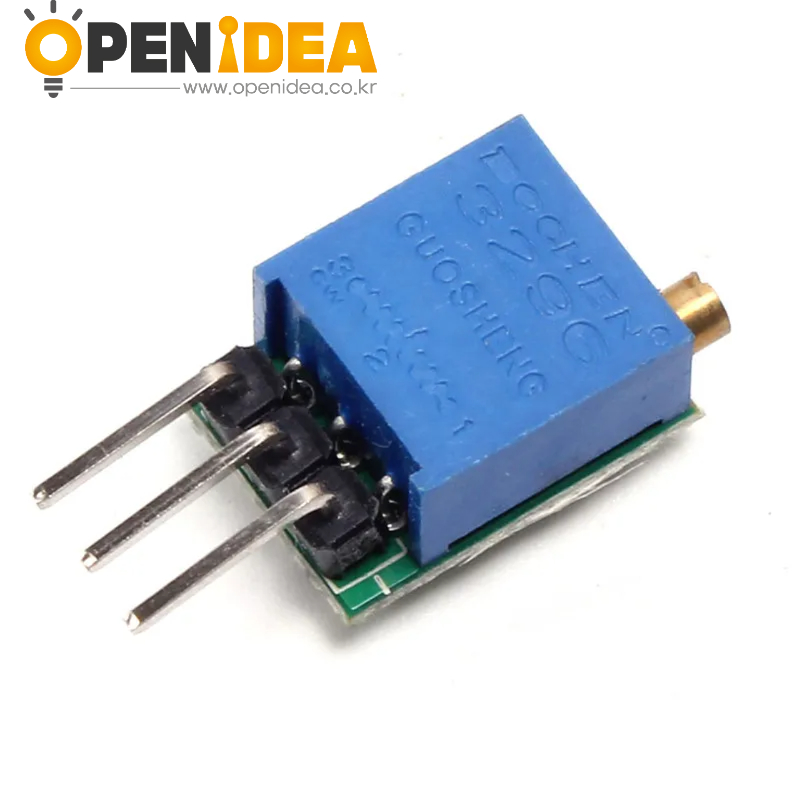

5 TP353 사각파 출력 NE555 모듈 발진기 가변 주파수 펄스 발생기 신호원 5kHz-250kHz DC 5-15V [ZTX101-179]

1,900 원

장바구니 담기

상품이 장바구니에 담겼습니다.

바로 확인하시겠습니까?

찜 리스트 담기

상품이 찜 리스트에 담겼습니다.

바로 확인하시겠습니까?

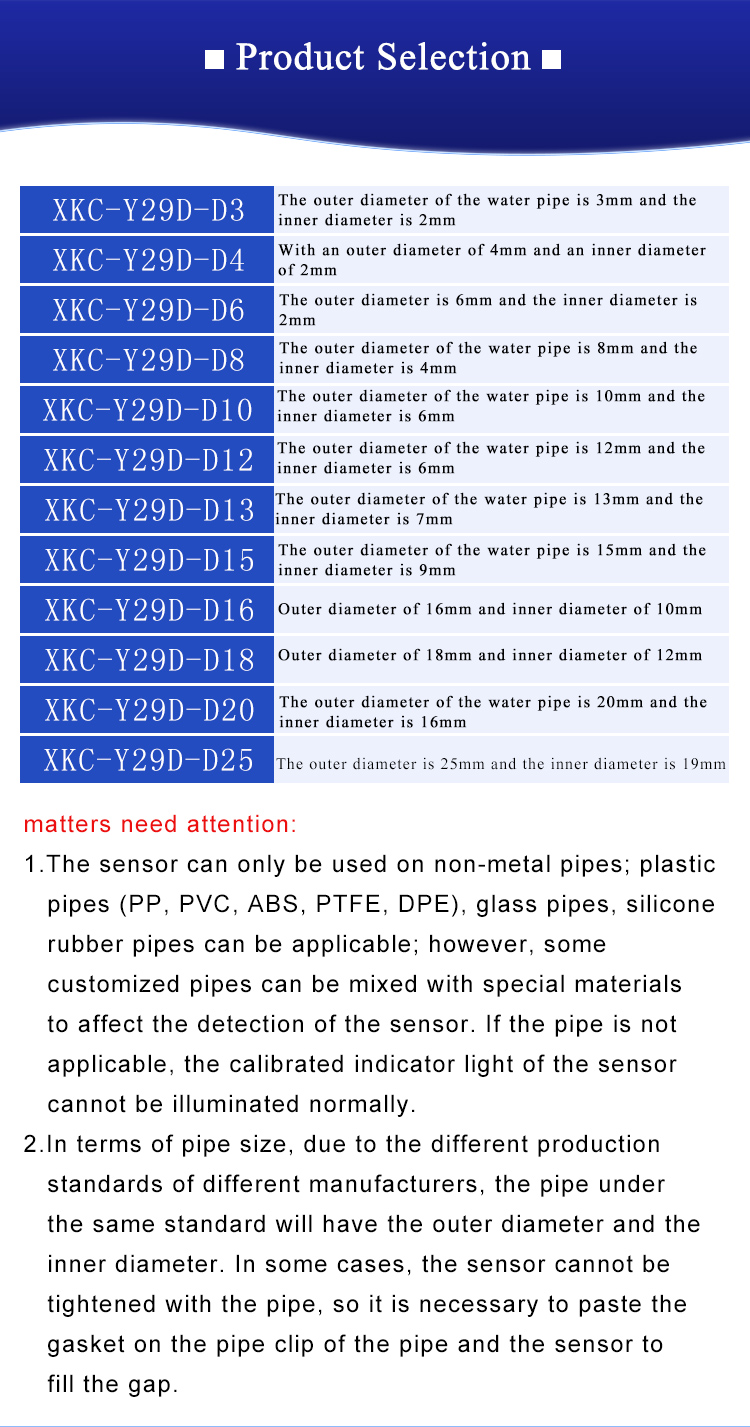

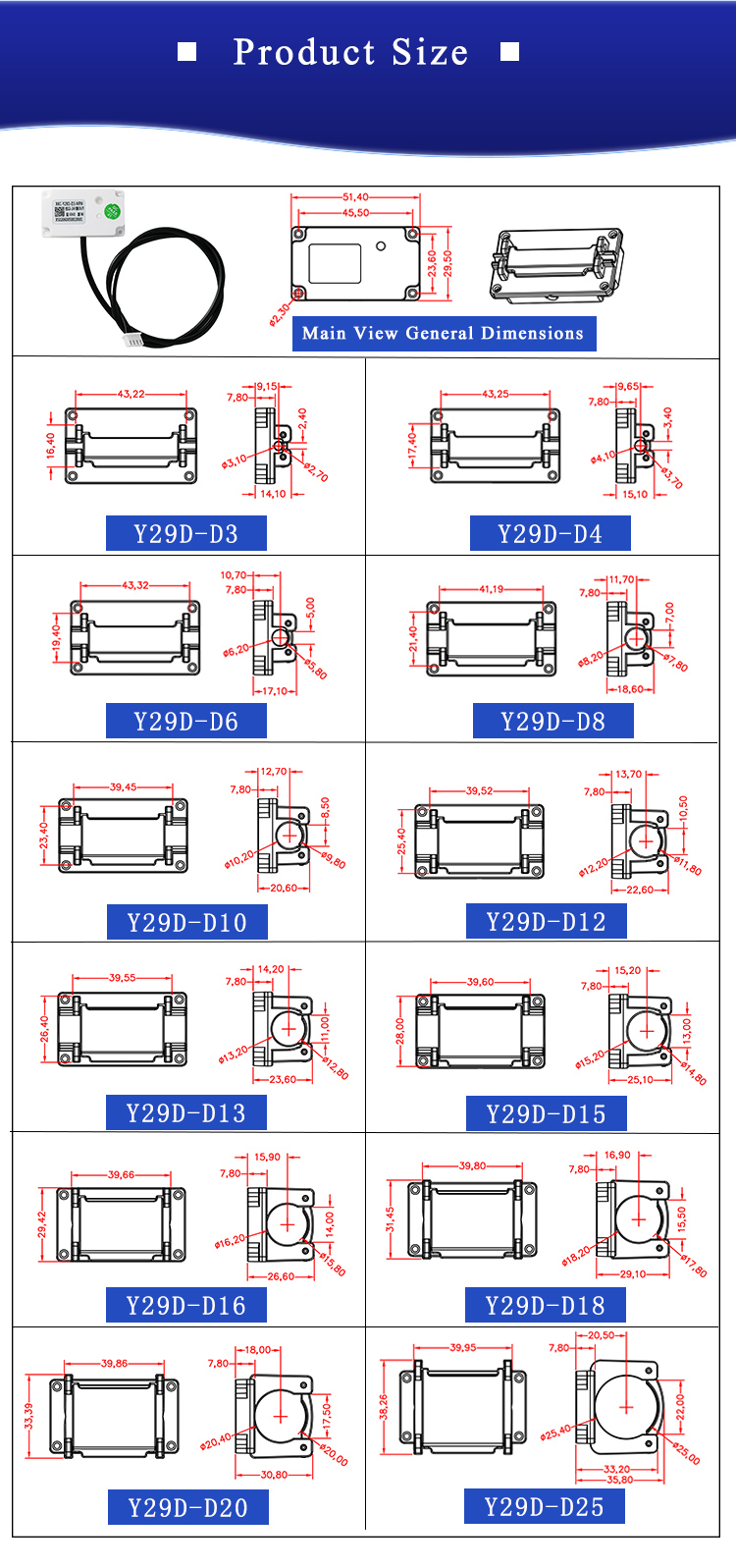

![Y29D 비접촉식 수위 센서 - 파이프 내부 액체 감지용 [XKC-16] Y29D 비접촉식 수위 센서 - 파이프 내부 액체 감지용 [XKC-16]](/data/editor/jpg/2025/07/18/06d075ecHa3bb0b8f8bcd40659a3861c92e5e42beC.jpg)

![Y29D 비접촉식 수위 센서 - 파이프 내부 액체 감지용 [XKC-16] Y29D 비접촉식 수위 센서 - 파이프 내부 액체 감지용 [XKC-16]](/data/editor/jpg/2025/07/18/46a375b7Ha3bb0b8f8bcd40659a3861c92e5e42beC.jpg)

![Y29D 비접촉식 수위 센서 - 파이프 내부 액체 감지용 [XKC-16] Y29D 비접촉식 수위 센서 - 파이프 내부 액체 감지용 [XKC-16]](/data/editor/jpg/2025/07/18/dc0735c2H5dd32acb22304246952ccdd3603b5db91.jpg)

![Y29D 비접촉식 수위 센서 - 파이프 내부 액체 감지용 [XKC-16] Y29D 비접촉식 수위 센서 - 파이프 내부 액체 감지용 [XKC-16]](/data/editor/jpg/2025/07/18/7ba68186Hef2be1170db446fcb1355b82140a85f2O.jpg)

![Y29D 비접촉식 수위 센서 - 파이프 내부 액체 감지용 [XKC-16] Y29D 비접촉식 수위 센서 - 파이프 내부 액체 감지용 [XKC-16]](/data/editor/jpg/2025/07/18/4670b64bHe87902b2c8074363b6ab8f51cf031ff28.jpg)

![Y29D 비접촉식 수위 센서 - 파이프 내부 액체 감지용 [XKC-16] Y29D 비접촉식 수위 센서 - 파이프 내부 액체 감지용 [XKC-16]](/data/editor/jpg/2025/07/18/5bca9915H7f4a151a4dcd47b9a2e20ea9de76dfebU.jpg)